Personal 3D Printer

It may come as a surprise, since I’m the Space Lead for 3D Printing at a local makerspace, but I’ve never owned my own 3D Printer. My first experiences with 3D printing were all on company provided machines during the era of tech companies where they provided random amenities (juice bars! snacks! ping-pong tables!) to try to keep programmers in the office as much as possible.

More recently, I re-started 3D printing at Asmbly, making custom bins for my Packout Organizers. I was observed trying to dial in the settings for my bins and asked if I wanted to take on the role of Space Lead. After confirming that detailed knowledge of 3D printer maintenance wasn’t a requirement (a mixture of figuring-it-out-as-I-go-along and asking the right people for help has served me well), I said “why not?”

One of the folks there wanted to find a good home for their Prusa Mini+, which wasn’t getting much use since they got a bigger printer. I thought “why not?” again, and bought the little machine. It’s an older model, but from a brand whose manuals and support I have really appreciated over the last year (4 of Asmbly’s 8 active printers are Prusas).

I’ve been speedrunning the standard 3D printer owner gauntlet. Benchy? Check. The printer’s first owner had set up a light bar and the semi-official base, which lets you keep the filament spool under the printer during the print.

But so many mods remained to be done… The base is designed for Prusa plastic spools, but most of my filament comes on cardboard spools, which don’t rotate as smoothly, so I printed a lazy susan using a skateboard bearing. To make space for it, I printed some leg extensions.

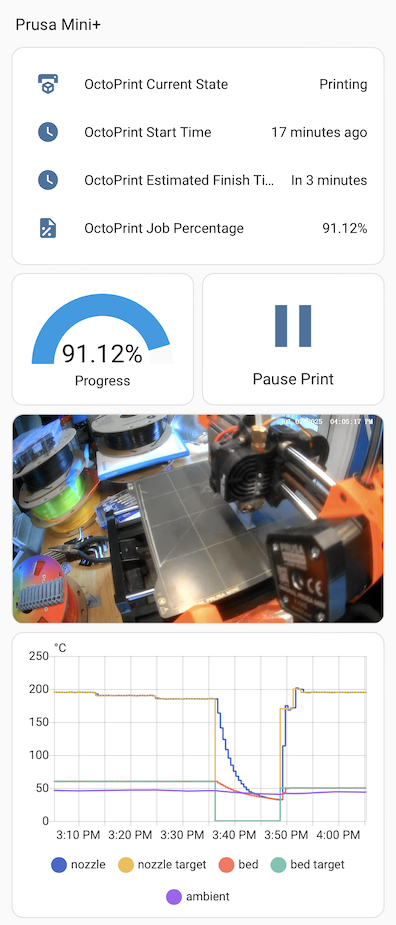

Sneakernetting a USB stick the six feet across the room from my computer to the printer was unacceptable, of course, so I set up a Raspberry Pi to run Octoprint. Can’t just have that sitting around, it needed its own integrated enclosure.

And I needed to have a camera pointed at it, so I don’t need to turn around to check its progress, so a camera arm was in order.

Naturally it’s all hooked up to home assistant…

What about printing stuff not for the printer itself? It’s been quite nice to have a much shorter testing cycle. I’ve been able to rapidly iterate on things that previously would have had a day turnaround. I’ve printed a few cat toys for Simone, a custom phone & watch stand for Adrienne, and a bunch of hooks for the wire shelving in the garage.

My next little project is to try different nozzle sizes. We have standardized on 0.4mm nozzles at Asmbly, but I want to see how much detail I can get with smaller nozzles.