School Again?

Well, I’d meant to write up some upgrades that I made to my home 3D Printer. I got frustrated with nozzle swapping the V6 nozzles used by the stock extruder, so I installed an E3D Revo hotend and got .25mm and .6mm nozzles in addition to the usual .4mm. And I upgraded to a Bondtech extruder. It’s ticking along pretty well now.

But I didn’t get around to that because I got distracted by school.

Machining

I’d tried to sign up for a class in the fall semester that covers how to run a CNC mill, but the registration was really weird. It’s technically a Continuing Education class, but I couldn’t sign up for it without permission from the department. When I finally managed to get in touch with the program coordinator (who’d been on vacation, it turns out), I was told that the class was a partnership with an apprentice program and that apprentices usually took all of the seats, but that I was 33rd on the waiting list for an 11 seat class. Oh well.

Randomly, I was talking to someone at Asmbly who said they were taking a machining class at ACC, and I asked them how. It turns out that the class I wanted to take was actually part of a three class series, and they’d registered for the first class, which would seamlessly lead into the class I wanted to take.

After a few calls, I got department approval to join the class two weeks late, and am now in the Machinist Apprentice Program, which runs from the summer semester into the fall.

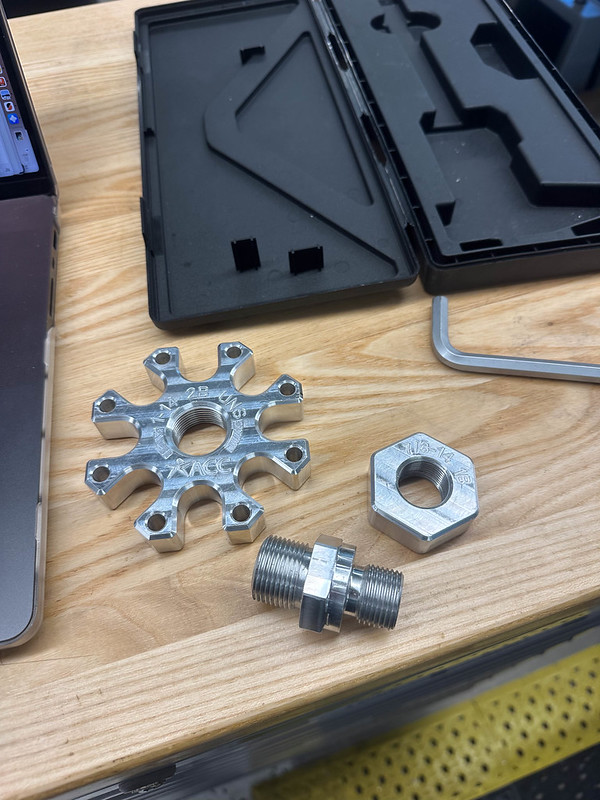

I’ve run through almost all of the required classwork for the three class series (which is more like a three class parallel, since the material for all of the classes is taught side-by-side), and have started focusing on designing and fabricating my own parts.

The class is taught on Haas Super Mini Mills and lathes, which are quite a bit nicer than the Tormach that Asmbly has. I may get spoiled…

Now that fall semester is underway, I’ve started two more classes…

Power Hammer

Sometimes, when you’re blacksmithing, you get tired of swinging a hammer quite so much. What if there were a machine that could do the hammering for you? Of course there is one: the power hammer. It uses a pneumatic piston to drive a heavy top die down towards a stationary bottom die. The ones that ACC has have pistons in the 40-75kg range, which is a wee bit heavier than a blacksmith’s hammer or even a sledgehammer.

I ended up doing a lot of work in the spring blacksmithing class using the fly press, which is a human-powered machine based on the same idea. The power hammers are startlingly faster at doing those same things.

We still end up using hammers and anvils, because there’s a lot of subtle work that doesn’t need huge amounts of force.

Jewelry Techniques 1

Jewelry Techniques I JLRY-1401

Rounding out my semester, I’m learning to work metal in yet another way. The introductory jewelry class had us start with a simple ring, a bracelet made with jump rings, and a stone setting (which I put onto another ring). The rest of the semester, we get to try to make whatever else we’re interested in, with a very experienced jeweler helping us figure out how to do it.

We’re cutting metal with a jeweler’s saw (my record for most blades broken in a day is 3), joining it by soldering with a cute tiny torch, and learning the basics of finishing and polishing.

I’m back to my usual geometric designs. I’m trying to make a dodecahedron pendant. I’ve done a prototype in copper and learned some things, and am now tackling it in silver.

I’ve also resized a bunch of rings for Adrienne and repaired one that had a broken joint.